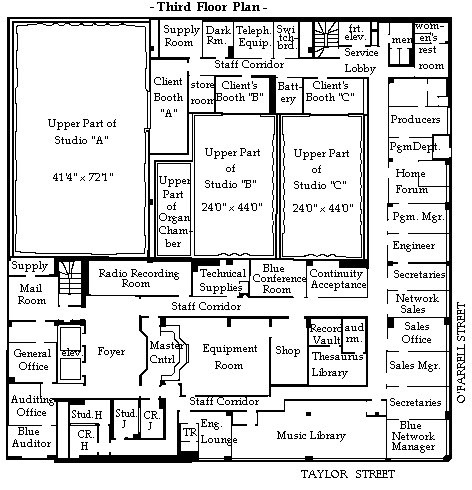

Fun and games in TV

Back to my roots

.jpg)

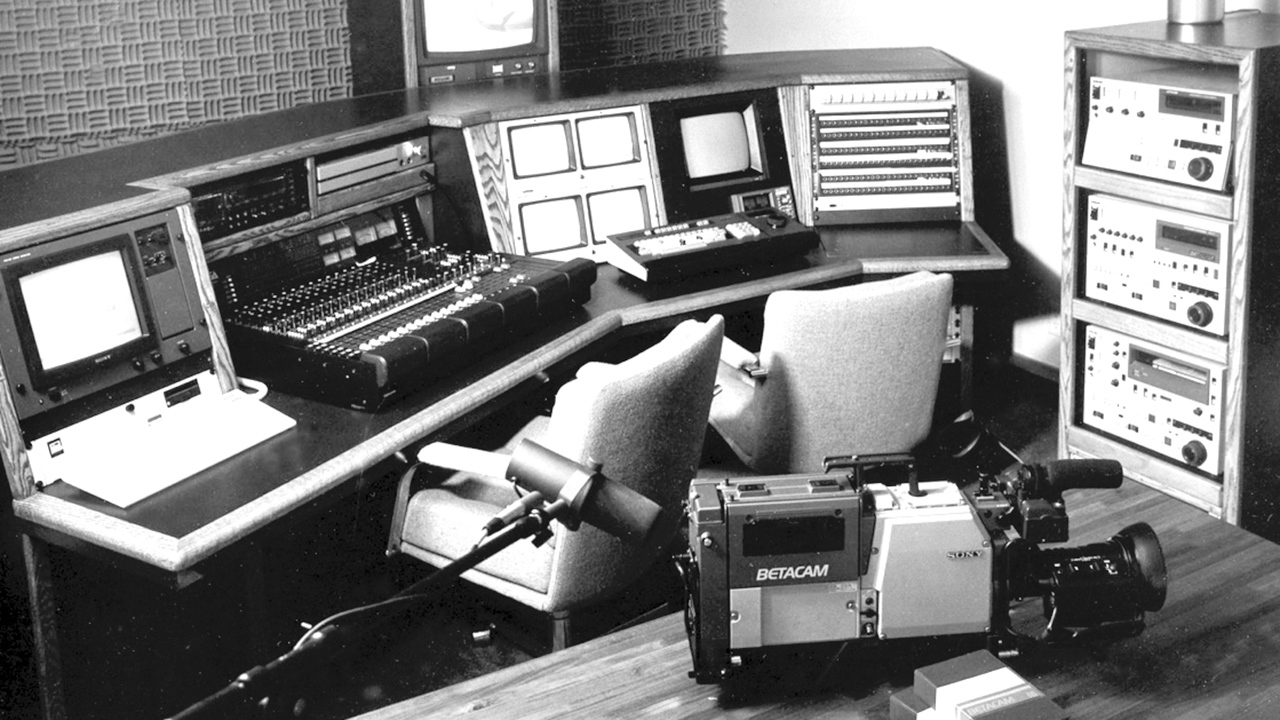

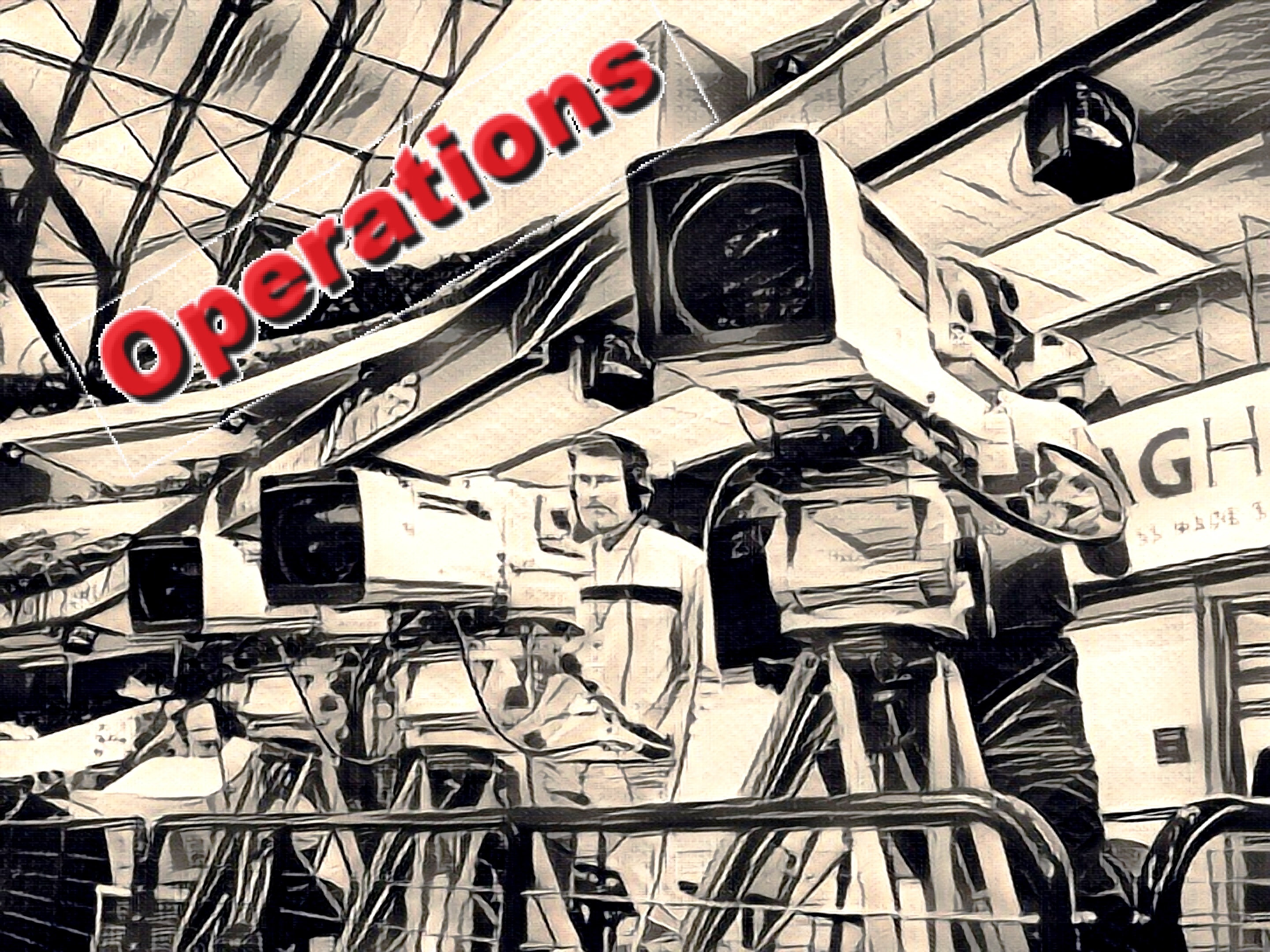

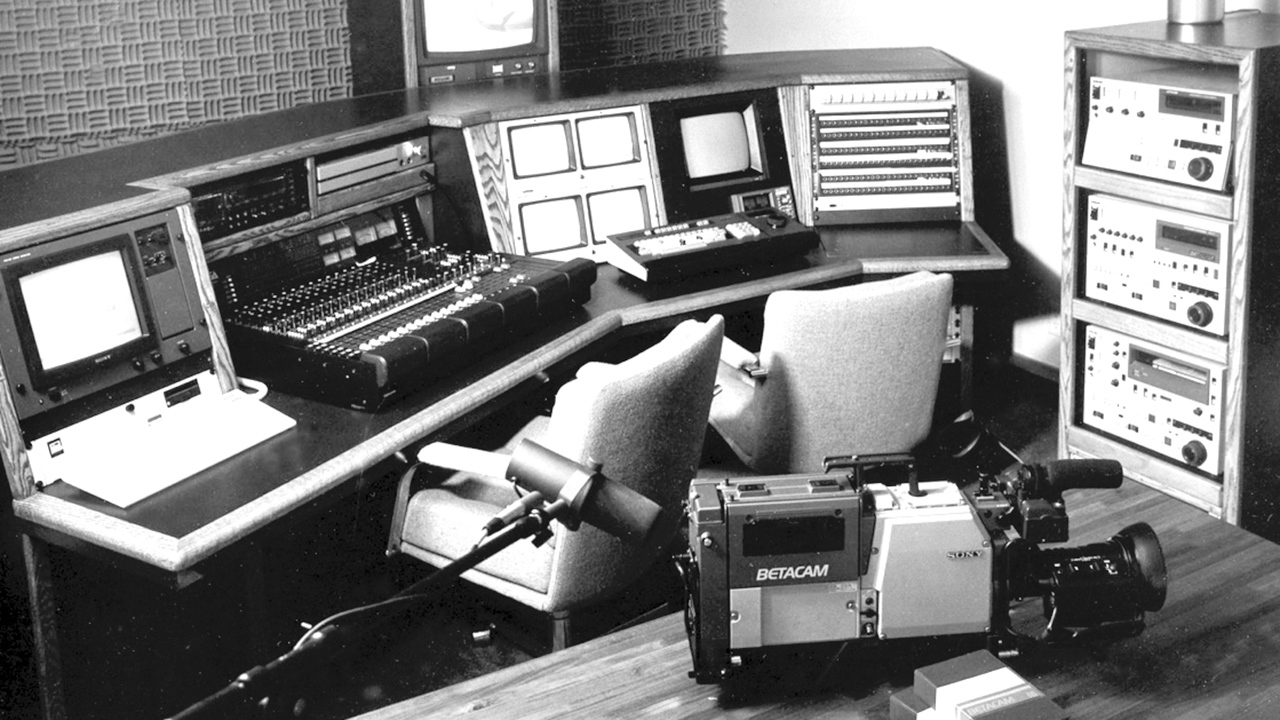

I worked on hundreds of different broadcast devices, most of which I was not trained on.

I worked on hundreds of different broadcast devices, most of which I was not trained on.

The equipment above is a sample of ones I was trained on.

Good times inside and out

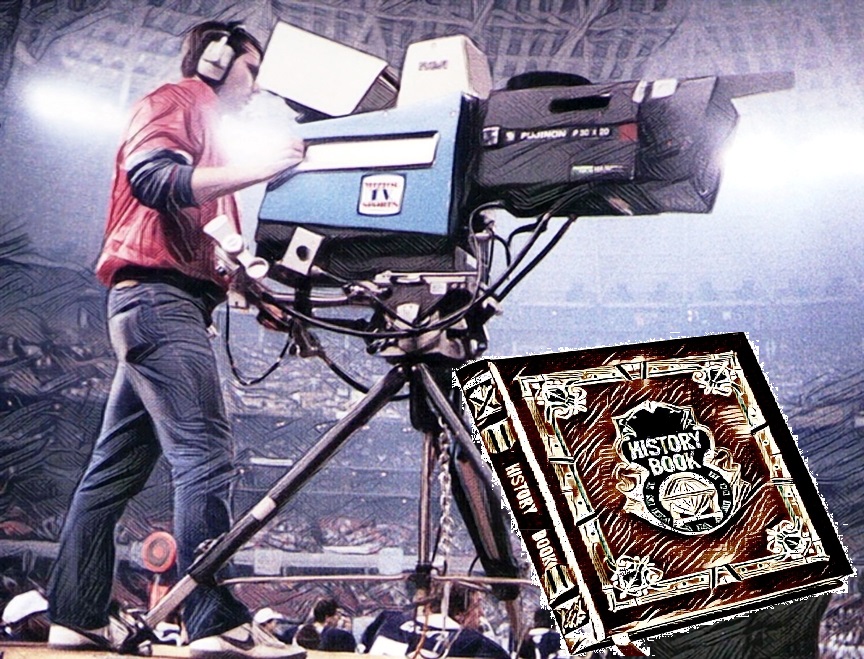

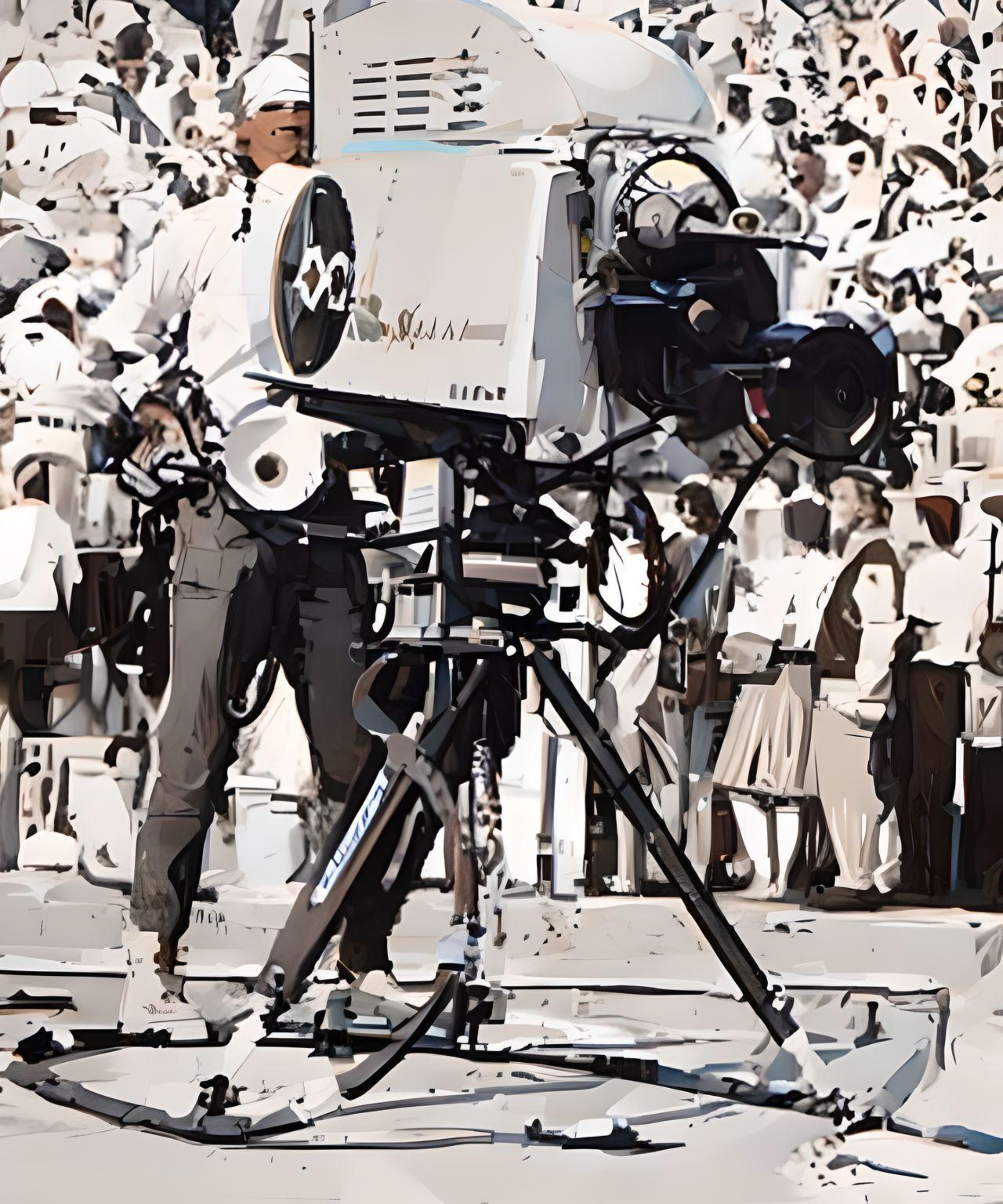

I ended up back in broadcasting, television, media, video, or whatever they call it today. In a way, it is more streaming now than anything else. I worked for three stations, one local to Sacramento. I also worked part‐time, or freelance, doing television production on location. In the vernacular, people in the industry know it as "remotes." Many people earn a living doing that.

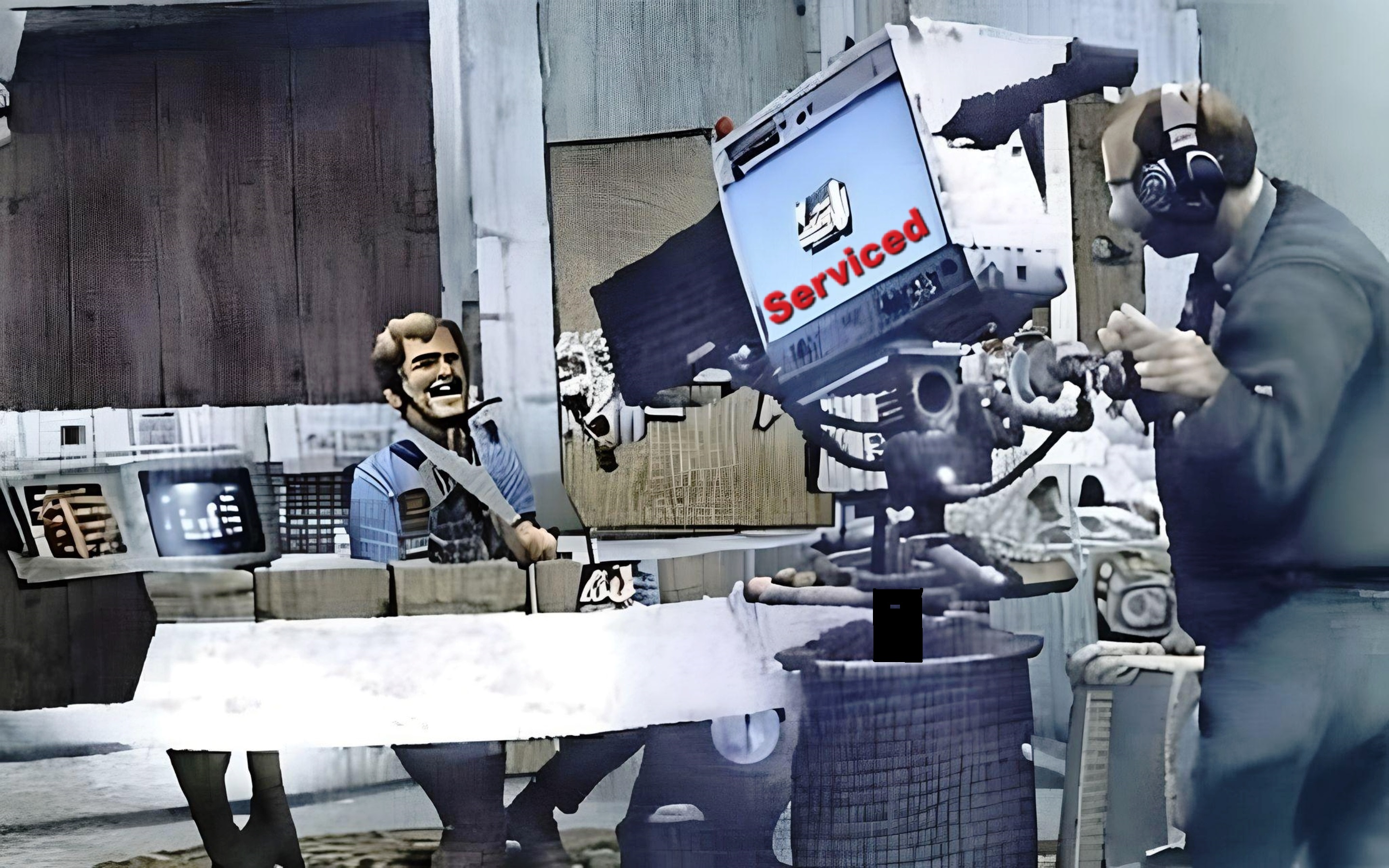

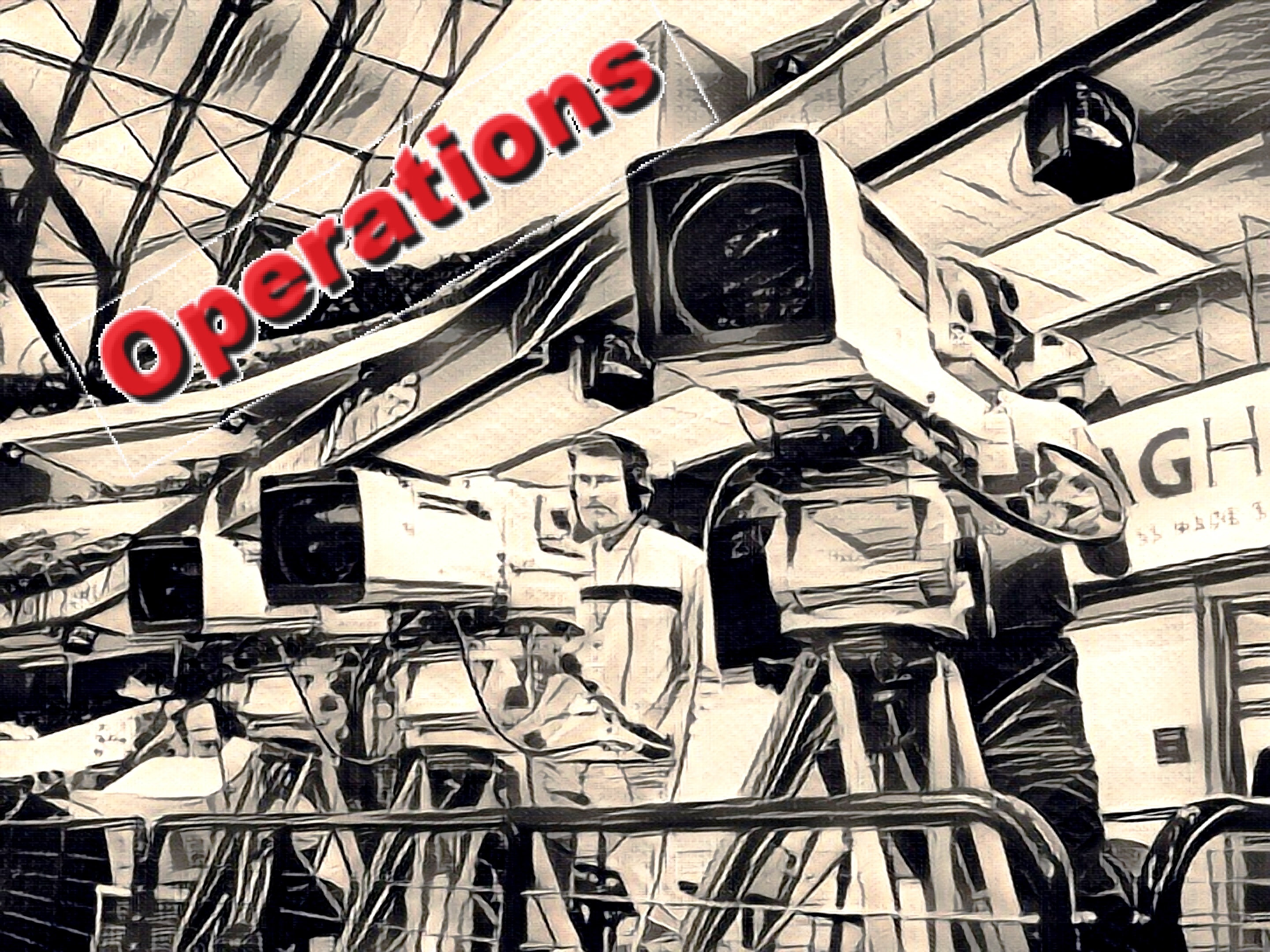

While I wasn't freelance, I spent a few years as an assistant, and then a EIC (Engineer In Charge) on a couple of production trucks. The title EIC is given to the person in charge of the technical aspects of the truck, or, as is usually the case, a trailer.

While I wasn't freelance, I spent a few years as an assistant, and then a EIC (Engineer In Charge) on a couple of production trucks. The title EIC is given to the person in charge of the technical aspects of the truck, or, as is usually the case, a trailer.

In other words the person who gets yelled at when the production's technical aspects runs of the rails.

In other words the person who gets yelled at when the production's technical aspects runs of the rails.

To continue the railroad analogy, the EIC usually lacks a degree in engineering. He is an engineer in the sense of solving problems on the spot. The industry often says a good EIC should think like a short‐order cook.

They should also have the triage skills of an EMT at a mass‐casualty event. When many things demand attention at once, what's done first? And, at times, even concurrently. The EIC needs an electronic technician's technical knowledge and the mindsets mentioned above. I was a C‐ and Ku‐band uplink truck operator/technician, also.

They should also have the triage skills of an EMT at a mass‐casualty event. When many things demand attention at once, what's done first? And, at times, even concurrently. The EIC needs an electronic technician's technical knowledge and the mindsets mentioned above. I was a C‐ and Ku‐band uplink truck operator/technician, also.

I designed and rebuilt portions of the facilities I worked in. I built several systems for the facilities' specialized needs. I repaired, maintained, and retrofitted almost everything found in a broadcast facility or on a truck (except plumbing!). I went through training on all the equipment shown above.

While almost all the equipment shown is old and out of date, I have on a few ocasions have been called on to use that expertize on antiquated equipment. That have included period exhibits at conventions and a trade show.

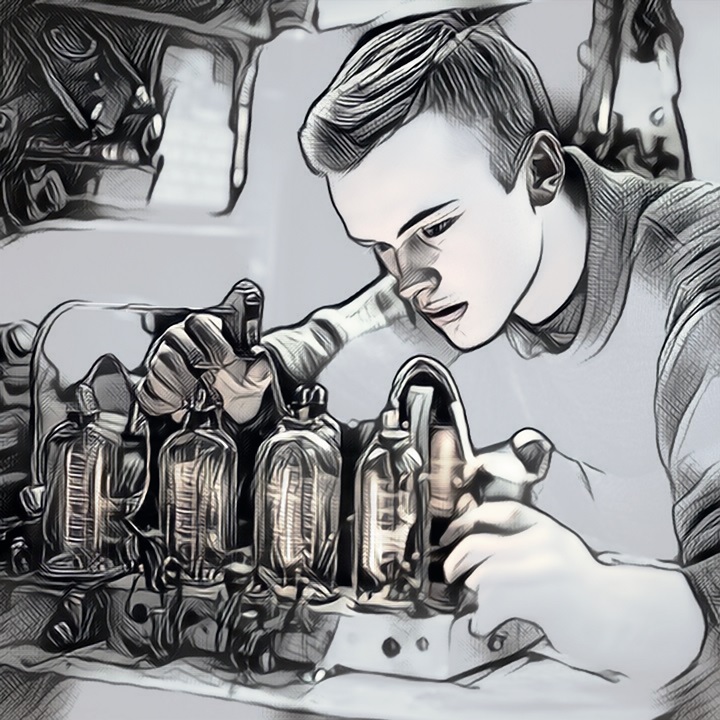

The most interesting was for GE Nuclear. Gamma rays wipe out CCD sensors in modern cameras within minutes when they inspect a nuclear reactor. A secret for a long time is that gamma rays randomly hitting earth, in far less levels of course, will occasionally take out a cell in a CCD device. You would see them as a black spec in the picture. CCD cameras have circuitry to mask that spot. It uses either the charge from the preceding cell or, in better cameras, the cells on either side of the bad cell. Very high‐end cameras would interpolate the value from the eight surrounding cells.Many cameras checked for these dead pixels when you selected automatic black balance on the camera.

Back to cameras and nuclear reactors. To the rescue of modern technology, 50s and 60s technology. CRT imaging devices. Usually, it was a tube known as the vidicon. In other cases it was known as a plumbicon.

The photo on the left compares the latest imaging tube to a CCD sensor. The right photo compares three generations of imaging tubes. The large one on the left is an Orthicon tube, developed in the 40s. The center one is a Vidicon, developed in the 50s. The right one is a Plumbicon, developed in the 60s and updated through the 80s.

GE had a slew of vidicon cameras that needed to be "retubed" and re‐aligned. Through a roundabout path, they found me, who knew enough about cameras, new and old, to do that. These were cameras they had bought used, very used in some cases. So they had not been exposed to radiation yet.

Equipment that had been inside a nuclear plant would be sent back in lead‐lined rail cars. It would be checked and repaired if needed. This activity was all done in what was called "hot zones." I took a half‐day training to work in "warm zones," where radiation levels were expected to be low. To work in the hot zones required multiple days of training. Something I elected not to do. Even in warm zones, I had to wear a dosimeter and be prepared to lose whatever I was wearing if I ever set off alarm bells. Which was possible upon leaving a warm zone. You went through what looked like a TSA scanner. But you had to stick your left arm down into a slot for the test. Never found out what that was about.

Setting up the newly acquired cameras took place in the warm zone. When a "hot" camera needed attention, I did what they do in a nuclear reactor. People trained for hot zones would point a camera at the inspected area. Then, engineers would direct what to do. The same with camera repair and setup.

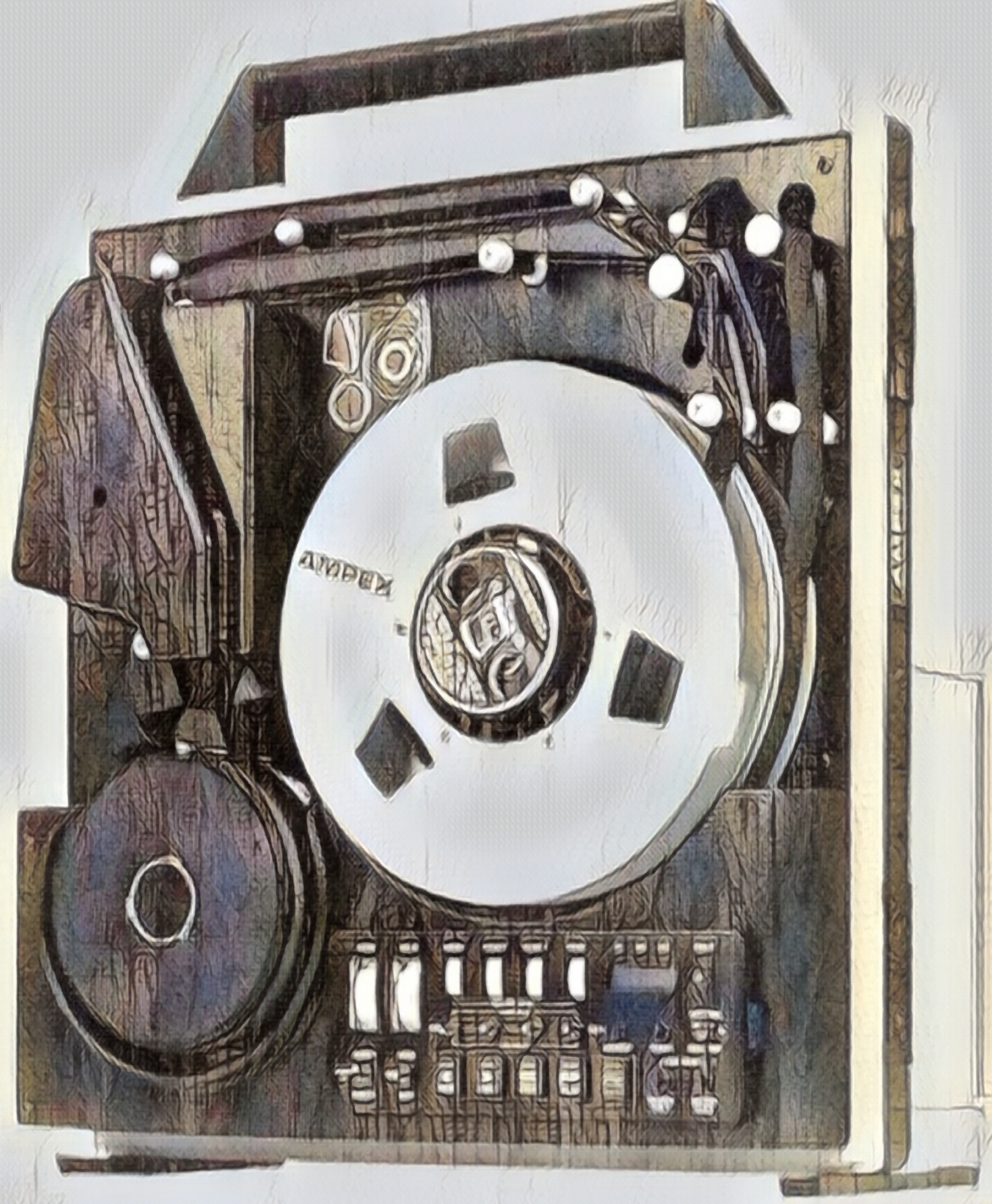

The first chance I had to play actual engineer came at a company named CMX. The name represented a joint venture between CBS and Memorex. When videotape first came into use, editors performed tape editing like film editing. It required the physical splicing of the tape.

A "small" edit suite in the late 80s.

CMX was a leader in video tape editing when it required a room full of equipment.

The CMX editing system had a DEC PDP‐11 mini‐computer with a whopping 64K of "core" memory. It also had two or more video tape machines (VTRs) and a interface box per VTR.

The beige and gray boxes shown here interfaced a single VTR with the CMX editor.

I went to work at CMX to design a new video distribution system in its development lab, something an electronic tech with a background in video could do. At the time there were three analog video standards in use across the globe. Every lab station had to have access to any of those three types of video signals. So I designed and installed the system, and then I had a lucky break.

Until then, each VTR vendor had a proprietary parallel interface to control their machine. Serial control systems, RS‐232, RS‐422, and others were on the horizon, but not in widespread use yet. This meant that CMX had to generate a new interface for each new machine. Sony had introduced a proprietary serial protocol.

At KCRA in Sacramento, they took early delivery of the same Sony machine. I designed and built an interface to control it from the production control rooms. CMX had just sold a system that required an interface to this machine. I told them of my design already in use. Although I still only had an Associate's Degree, I was promoted to an engineer. I worked on a couple of other machine interfaces. I redesigned their base time code reader to fit on a single PCB and eliminate the two it then needed.

I was part of what CMX called its "interface group." There was also a "systems group" that mainly wrote code for the "supervisor," which was the DEC PDP‐11. The RS‐422 interface soon quickly became standard on almost all VTRs. Over time, VTR vendors settled on a few different serial protocols. But the RS‐422 hardware stayed the same, no matter the software driving it. Being a hardware engineer and in the interface group, I became "surplus."

I was offered a job at a startup by a former mentor. Look up "minimum Johnson" above. The company was designing a Point of Sale (POS) geared for McDonalds. I finished the design of the video circuitry used in the system's terminal. I then set up the product test facilities. I led the effort to get UL acceptance and compliance.

The company designed each terminal as a stand‐alone device. It needed no backroom computer. Multiple terminals each held all the sales data. On startup, a random terminal would become the principal, or "score keeper" as they called it. It would collect data from the other terminals, compile it, and distribute it back out for all terminals to have. The terminals used a very early version of Ethernet. It was before the OSI stack was standardized.

The design flaw that killed the company was its app. It was written in Forth and only resided in battery‐backed RAM. PROM held only bootstrap code. It loaded the app from another terminal if it had a corrupted app. A bug, thought unlikely, was triggered at the very first installation. A corrupted app in one terminal pushed its bad code to the others. Took the entire system down. A system that was intended to be failsafe was not.

Stopped the company in its tracks. Learned first hand that sometimes a company can get out over its skis technologically.

Decided it was time to go back to school.

.jpg)

While I wasn't freelance, I spent a few years as an assistant, and then a EIC (Engineer In Charge) on a couple of production trucks. The title EIC is given to the person in charge of the technical aspects of the truck, or, as is usually the case, a trailer.

While I wasn't freelance, I spent a few years as an assistant, and then a EIC (Engineer In Charge) on a couple of production trucks. The title EIC is given to the person in charge of the technical aspects of the truck, or, as is usually the case, a trailer. In other words the person who gets yelled at when the production's technical aspects runs of the rails.

In other words the person who gets yelled at when the production's technical aspects runs of the rails.

They should also have the triage skills of an EMT at a mass‐casualty event. When many things demand attention at once, what's done first? And, at times, even concurrently. The EIC needs an electronic technician's technical knowledge and the mindsets mentioned above. I was a C‐ and Ku‐band uplink truck operator/technician, also.

They should also have the triage skills of an EMT at a mass‐casualty event. When many things demand attention at once, what's done first? And, at times, even concurrently. The EIC needs an electronic technician's technical knowledge and the mindsets mentioned above. I was a C‐ and Ku‐band uplink truck operator/technician, also.